Using laser technology to collect essential data during Covid 19

We can rely on 3D laser scanning technology to advance projects amid the new economic landscape, writes senior survey technologist Trevor Pasika of Canadian design company Stantec.

If a project team can’t go to a site to collect essential data, the site can now come to them. Rather than sending multiple staff or various discipline leads to locations that may be remote or congested, all the essential design information, photos, and measurements can be captured and stored by a laser scanner.

The best part? You only need a team of one to operate the scanner capable of measuring over a million points per second. Whether for a single location or a project located on multiples sites, laser scanners could be the only way to gather essential information amid COVID-19 social distancing regulations and travel restrictions.

Trevor Pasika.

With the help of 3D laser scanning (3DLS) technology, project teams can capture up-to-date, detailed, and accurate three-dimensional information from either a specific area or an entire facility with all its observable components.

An essential step in a project life that would normally require a survey crew and a few site trips can now be completed in a matter of hours by a trained technician equipped with a laser scanner.

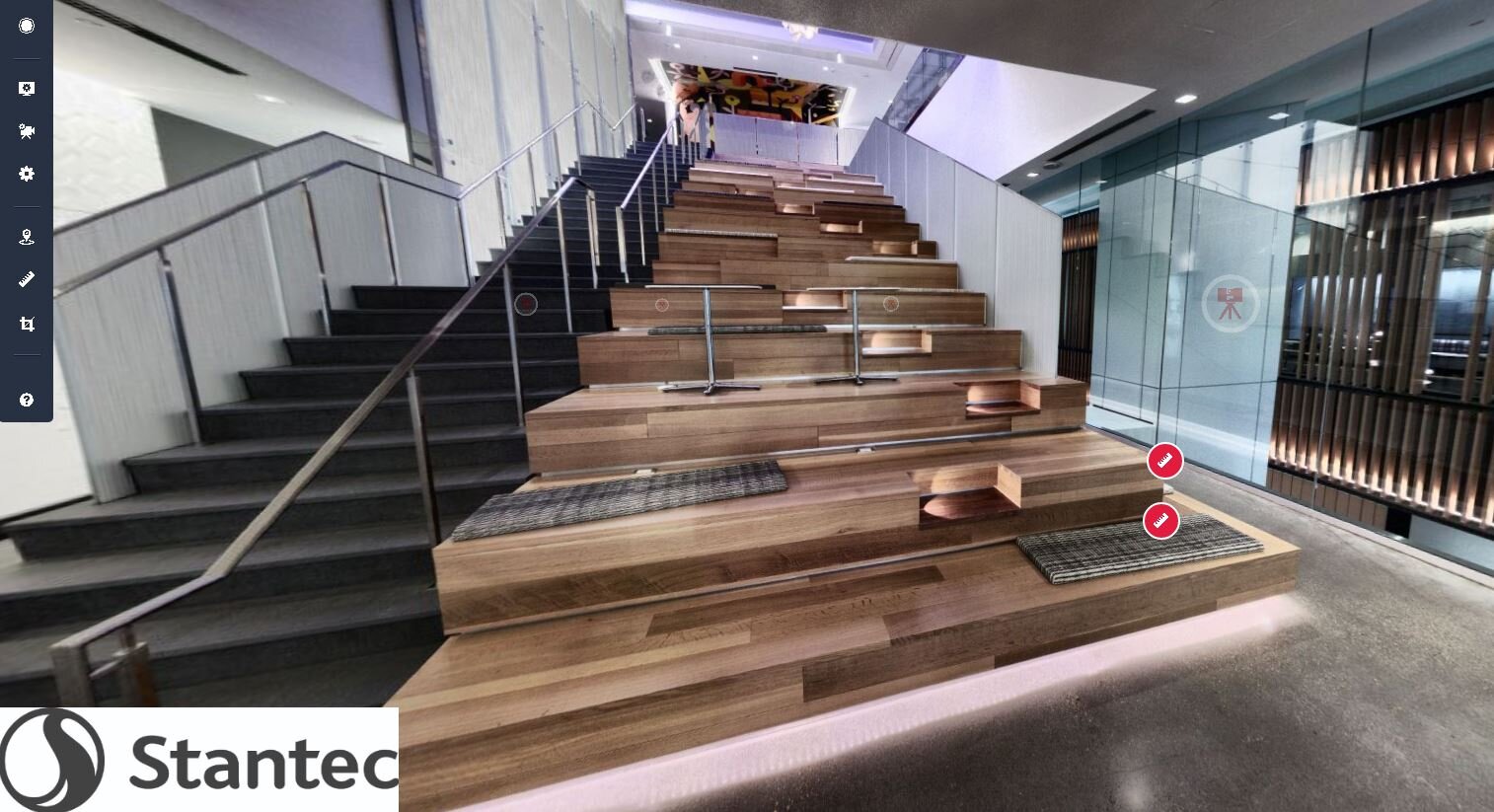

An image from a virtual tour of a site using a point cloud viewer.

The scanner detects objects within its visible line of sight all while completing 360-degree horizontal and 300-degree vertical measurements. The result? Volumes of high-quality high-dynamic range (HDR) imagery and 3D points collected in a fraction of the time it would have taken a field team to gather. With a full 360-degree capture range and ability to pick up objects in the dark, the scanner sees objects from multiple points of view. Given the level of detail in the data pulled from a single site visit, there’s a good chance that the full 360-degree scans capture enough information to cover any future needs of a project if the scope or design change.

Once 3D scans are collected, the design team processes the files and stitches them together to create a complete point cloud data model. Point cloud and HDR imagery can be hosted on a web-based platform that brings the site to the design team, giving them the ability to take a virtual tour of a facility from their desktops, as well as easily access, view, and measure the collected data. What’s more, collaboration is built right into the technology, allowing project teams and clients to mark up the information, leave annotations, and import new design models.

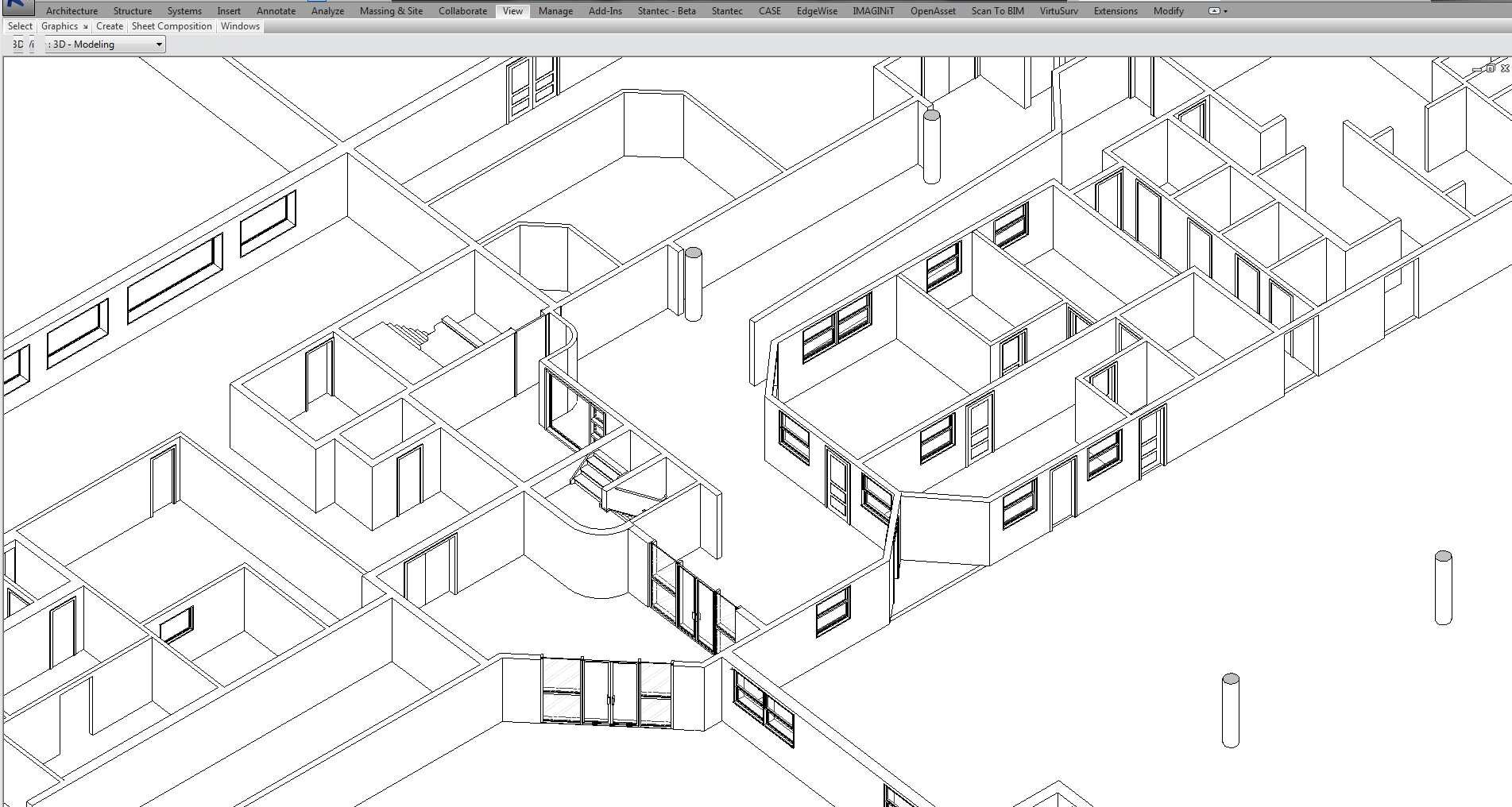

As-built Revit model derived from 3DLS.

Stantec has been using laser scanners since 2008 on building, mining, and complex industrial projects. Most recently, our team has seen an increase in the use of 3DLS on transportation initiatives. Instead of sending surveyors to take measurements within a roadway, a laser scanner technician can capture the same data from a sidewalk, significantly reducing the risk of an accident.

For one of our clients who manages over a dozen of sites, we brought in laser scanners to gather essential design information while following social distancing recommendations and reducing our footprint in the area. The typical process would normally involve gathering a team and sending them to mark up all the locations, take photos, and collect data for as-built drawings. Using 3DLS technology on this project cut the size of the survey crew down to two people—a client representative and a laser scanner technician—saving the project team 14 site visits. The same people that would have been sent to the project locations for a walk-through can now do it virtually from their desktops—or even smartphones.

Point cloud model layered on top of the Revit model.

Our Stantec team will be using the technology on a project in Ontario. Rather than deploying a large crew to scour the site and capture all its nuances, we will be sending a trained technician with a laser scanner to bring comprehensive data to the design team. By using 3DLS on this specific project, we will be able to gather more data in less time and reduce our impact on the client’s business operations.

While the challenges associated with our COVID-19 world make 3DLS an important option to keep projects moving, the technology will benefit clients and designers long after the pandemic is gone.

Trevor Pasika is a senior survey technologist at Stantec, an international design and consulting company based in Canada. He’s worked on a diverse range of projects including industrial, transportation, community development, buildings and environmental services.